Home |

Motorcycle Main page |

Material |

Theory |

Installation |

Testing |

Links

Introduction

So you wonder why you'd want to use heated grips on your motorcycle?

Well, even if you ride only in summer I'm sure you already were in

situations where you wished you had warmer fingers. Such as a

ride in the evening, over a pass in the mountains, or in a downpour

when your gloves got wet and you did not have those warm spare gloves

with you.

I started building my first set of heated grips when I got my Suzuki

GSX250E and at that time the motorcycle was my only means of transportation

(poor student that I was ;-). Since then, most of my motorcycles have been

equipped with this "extra".

Today, you can buy heated grips at motorcycle accessory shops and several brands

may deliver them even ex factory with this accessory. For those who want to

build their heated grips themselves, here are some hints.

Material

A heated grip is nothing else than an electrical wire that is embedded

inside the rubber of the grips of the motorcycle. If electrical current

passes through the wire, it gets warm just like any electrical heater

you use in your house.

In the design described below, I have wrapped such a wire around the grips of my motorcycle and fixed them with heat shrink tube (german:

Schrumpfschlauch, french: thermoretractable).

The wires are then connected to the electrical system of the motorcycle (switched +12 V on one end, ground on the other).

A switch allows to turn them on and off and another position of this switch allows to use a setting with reduced heating power.

Of course you can also use an electronic regulator :-)

First of all, I assume that you have some practical experience with

maintaining your motorcycle. You should be able to read electrical

wiring diagrams and to find which cable is located where.

The usual disclaimer: These are things that I did myself on my own

motorcycles. Most of it should also be applicable for other models,

but if you repeat this with your bike, you do it on your own risk.

You will need the following material (the "why and how" are discussed

in the text below):

- a length of Constantan (german: Konstantan) wire, preferably of 0.4 mm diameter and about 1.5 m per grip

(if you use another diameter and/or another wire material, you will need a different length.

For the calculations see below).

If you have trouble finding Constantan wire, look in an electronics catalogue under "resistance wire" or try a school material supplier:

Constantan wire is used quite often to demonstrate Ohm's law.

- Two pieces of heat shrink tube 125 x 50 mm, preferably with thermal glue.

The type I used was IMCS-A 50/18 mm, which costs about 30 CHF per meter if you buy small quantities

(many thanks to Christoph Buehler from Rotima in Switzerland for directing me to a suitable material!).

Basically any rugged shrinking tube with thermal glue should do the job.

- A ceramic resistor 2.2 Ohms/20 W, or a suitable length of Constantan wire that is wrapped into isolated tubing.

- A small On-Off-On switch than can switch at least 4 A and be attached to a suitable place on the bike.

- As an alternative to the two items above: an an electronic regulator.

- A few meters of thin, highly flexible coaxial cable such as RG174. Although there is no "technical need" to use coaxial cable (you can use

any cable that you have at hand) I found it more practical - and more elegant - to feed a single cable to each grip.

- Some standard cables, cable binders, self-adhesive textile tape, and a few crimp-on electrical connectors for car/motorcycle electrics.

As for the tools, you will need a good multi-tester, an electrical

soldering iron (40+ W recommended), a heat gun and the usual tools

for cutting wires.

In the first trials I thought of using copper wire for the heater

winding, but found that the typical resistance of copper is too low

- it would require either a very fine (read: fragile) or a very long

(read: not practical) wire. I found that Konstantan is a very suitable

alternative: Konstantan is a Cu/Ni alloy with a fairly high typical

resistance, does not change its resistance with temperature (hence

the name), is mechanically robust and can be soldered with a standard

soldering tool.

By the way, Konstantan/Copper makes a nice thermocouple with a

pretty large EMF. Thus, if you want to measure the temperature of your

engine, why not take a copper and a Konstantan wire and crimp them

together at the tip?

Calculations

The power requirements for heated grips depend on the ambient temperature

and on your individual perception. I found that a maximum power of

about 25 W per grip is probably sufficient for all situations. A

second setting with reduced power of 8...12 W is suitable to keep

your hands warm under not-so-cold conditions and of course you may

also introduce a variable power control to adapt heating power to

all situations (see below).

At the same time, power consumption should be low enough not to thread

the rest of the electrical system of your motorcycles. Two grips with

25 W each correspond roughly to an auxiliary headlight and should be

compatible with almost any modern motorcycle.

I wired both grips in parallel. This has the advantage that if one grip fails

(for whatever reason, such a a broken wire inside the winding), the other remains

functional.

The required length of the wire depends on its material and its

diameter. What is needed is to have the "right" resistance to get

the desired heat dissipation per grip.

The calculation of the required resistance is simply done using Ohm's

law (R=U/I) and the definition of electrical power (P=U*I). Combined

they give the formula to express the dependance of power from

voltage and resistance, P=U2/R.

Thus, to consume about 25 Watts, use a length of wire that

has a resistance of roughly 5.8 Ohms per grip.

Please note that the exact resistance does

not matter that much; you probably won't feel if it's 23 or 26 Watts.

I build my heated grips with Konstantan wire of 0.4 mm diameter,

which has a resistance of 3.9 Ohms per meter. Using a length

of 1.5 m of the above Konstantan wire per grip yields a power

dissipation of 25 W at 12 V and of 31 W at 13.6 V.

For the "reduced power" switch setting, the calculation is the

same, but the two grips are switched in parallel and then in series

with an additional resistor. With a 2.2 Ohm resistor, the

remaining heating power on the grips is 8 W at 12 V and 10 W at

13.6 V. The heat dissipation of this resistor is

about 16 W, so do not use standard carbon resistors. Ceramic

resistors are designed to get pretty hot without failing and they are cheap.

Some manufacturers use a resistance wire that forms an integral part of the

hotgrip wiring - also a nice way to dissipate the heat over a large area!

A much more elegant solution to control the power to the heated grips is an electronic regulator

based on a pulse modulator. In this setup, an oscillator switches a transistor "on" and "off"

at a frequency in the lower-Hz range (reportedly, higher switching frequencies can lead to

interference with some equipement). I sell suitable control units here.

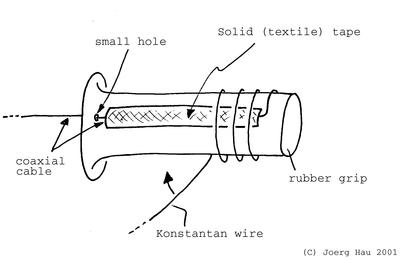

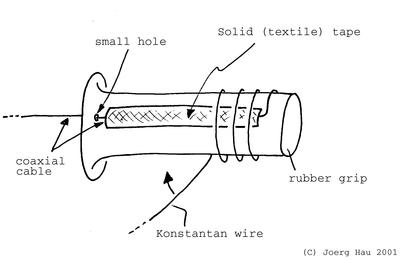

Putting it together

A mechanical problem is related to the movement of the right grip,

which is of course used to control the throttle. A very flexible wiring

should be used here and I have used a thin coaxial cable of the RG-158

type (standard RG-58 is too thick). Both grips are prepared in the

same way:

Drill a small hole on the "inner" end of the grip, so that you

can pass the coaxial cable through it. Cut out a small slit in the

rubber of the grip so that you can hide the coaxial cable in there

- otherwise, you will always feel that cable later on and I can assure

you that this is not what you want ;-).

Feed the coaxial cable through the hole. Remove the outer isolation of this

cable so that the shielding is located at the "inner'' end of

the handle and the inner ("hot'') wire goes to the outermost

end of it. Press the cable in the slit described above and attach

it with a length of textile tape (use textile tape, no plastic).

Cut the required length of Konstantan wire. Solder one end to the

"hot wire" of the coaxial cable. Konstantan can be soldered

with standard electronic solder, but soldering surfaces should be

perfectly clean.

Now start wrapping the wire around the rubber grip. You may want to

use a short piece of textile tape to attach the winding from time

to time.

Make a node in the wire to fix the last winding, then solder it carefully

to the other end (shielding) of the coaxial cable. Use an Ohmmeter

to verify that you have the right resistance - neither a short circuit,

nor an open winding.

Now use a suitable piece of thermo-retractable tubing to fix the whole

assembly. You will need a heat gun for this; I do not recommend using

an open flame! Initially I used some cheap, thin tubing, but this

tends to get brittle over the years. Recently I replaced it with some

thick-walled tubing that is additionally equipped with a layer of

thermal glue - that is, when you heat the tubing it shrinks and the

glue melts, fixing the whole assemble very neatly to the grips. This

reduces mechanical stretch to the wires and it provides additional

protection by excluding water (due to the glue). The type I used was

IMCS-A 50/18 mm.

Practical notes

- I strongly recommend to start wrapping from the "outside" of the grips,

as described above: It is easier to solder the resistance wire to the

coaxial cable first. You can then wrap the wire, finally fix it with a node

to the shielding and then calmly solder it. If you proceed the other

way round, you will need more than two hands ;-)

- Another trick is to solder each end of the coaxial cable to a short length

of standard wire ("Schaltdraht") first and then to use these two pieces of wire

to connect to the Konstantan wire. This avoids potential trouble with the "soft"

isolation of many coaxial cables.

- When finished, the cables are fed "below" the grips and from there

they are simply attached to the existing tubing that holds the motorcycle's

wiring. If you use black wires and cable binders, they will be almost

invisible.

Once you have finished wiring the grips and verified the electrical

values, it's time to hook up the whole thing to the electrical system

of the bike. Disconnect the ignition (better: the the battery) while

you do this installation!

Connect the two shield wires of the coaxial cables together and do

the same with the "inner" wires. Verify the resistance again;

you should get half the value you measured above as both are now

used in parallel.

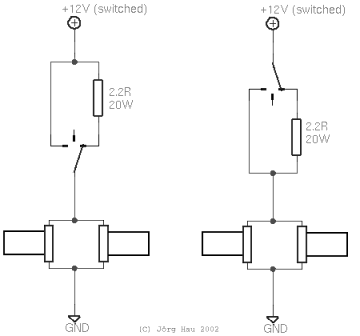

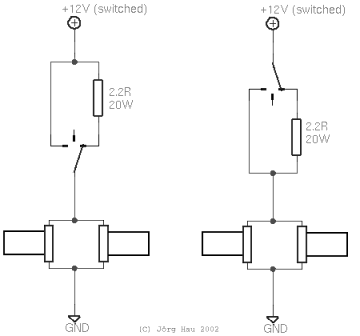

The wiring is shown in the diagrams; there are at least two alternatives

possible. Select the one that fits your needs.

Practical notes:

- Connect the shielding of the coaxial cable to ground (Kl. 31) and connect the

"inner" wire to the "hot" line. If ever the cable isolation is worn off,

this will avoid a short circuit with the frame.

- The +12 V line (Kl. 15) must be a fused

line that is switched with the ignition. My BMW R80GS

has a suitable circuit that is also used for the auxiliary plug (under the

seat) and that is fused with 7.5 A. The "deluxe" version is to

use a relay that is switched with the ignition and that provides

+12 V to the grips.

- The On-Off-On switch must be able to switch 4 A. I used a

small switch that I packed into a small, home-made aluminium case,

sealed with epoxy glue and that is in turn attached to the left

handlebar of the bike - see the picture above.

- The 2.2 Ohms power resistor is electrically isolated and is mounted

on a well-ventilated place close to the frame under the gas tank.

Now you are ready to test. Re-verify everything, reconnect the battery,

and turn the ignition on. If you switch the grips on, you should note

that they get warm after a few seconds (it may take a while).

Keep in mind that the diameter of your handlebars has now changed,

due to the wall thickness of the shrinking tube. Be aware of a somewhat

changed "feeling'' for you bike when you ride it the first few

times now. In addition, the "grip'' of the handlebars has changed

- this is no longer rubber but rather smooth plastic. Personally I

did not have problems with that, but if you use nylon gloves to protect

you from rain you may encounter the problem that the throttle grip

might slip somewhat under your gloves. You have been warned.

What else remains to say? Have a good season, whatever the weather

may be!